I installed an inexpensive dehumidifier with a short run of duct to return the air outside a bathroom. It’s been a huge help for humidity and comfort.

Looks like the replacement for the PAC-SDW01RC-1 thermostat is finally coming out! The PAC-SDW01RC-2! But also there is a 03 launching soon!

I've had problems with the -1 where a power cycle would cause the thermostat to read from the incorrect temperature sensor, switching from the thermostat to the sensor inside the air handler. This lead to being 5-10 degrees off from the room temperature! I'm waiting on my HVAC contractor to get a unit and try replacing it.

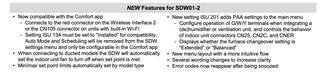

Besides the fix, I'm glad to see WiFI integration as well! I don't use the Kumo Cloud unit but instead use a ZWave connector with a minisplit. I'd like to get the air handler integrated.

No idea with the 3 revision does though!

HVAC Journey: Mitsubishi Equivalent Pipe Length

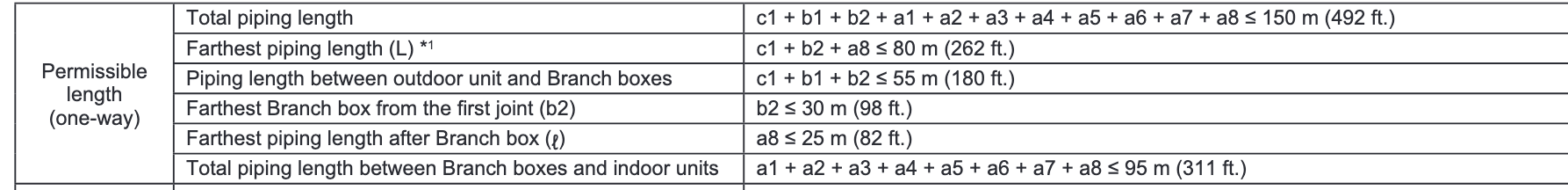

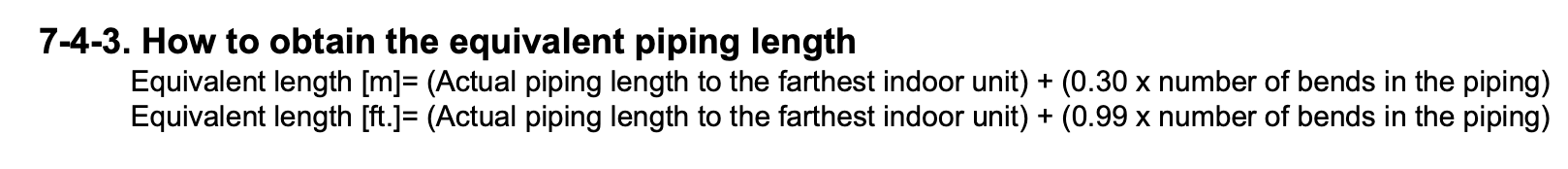

Posted onWhile trying to debug problems with my HVAC system I came across "equivalent pipe length". Mitsubishi seems to omit this from installation manuals but includes it in their engineering manuals.

Equivalent Pipe Length accounts for the pressure drop of fittings, valves, or bends in a line to help simplify limits for a system. If a system has a max line length of 100' the measured distance of 100' would assume no additional parts in line to drop the pressure. If you add fittings, valves, or bends then the measured length would need to be below 100' to stay within the system limits specified as equivalent pipe length.

An example

As a practical example. Here is my system (as best I could model in Diamond System Builder):

I have a single outdoor unit with 4 indoor units: a central air handler and 3 mini splits. The lengths listed in this diagram are the measured lengths. The system will calculate the equivalent pipe length automatically and check it against the equipment specifications listed, pretty cool.

I cannot however correctly model my system in Diamond System Builder though as the measured length for the Front Bedroom is 84', with 6 bends.

For my outdoor unit. The installation manual states the Farthest piping length after Branch box of 82'. The 82' is the equivalent pipe length NOT the measured pipe length.

I've confirmed with a Mitsubishi representative that the installation manual uses the equivalent pipe length, not the measured pipe length. This aligns with the System Builder where I can input 82' if I use 0 bends. The max length I can use with the 6 real-world bends in my system is 76'.

In the engineering manual there is a calculation for the equivalent pipe length on this system:

Which is why I can only input 76' feet with 6 bends (76' + 6 * 0.99' = 81.94').

How would someone know

I'm not sure how someone would know the installation manual uses equivalent pipe length. Maybe this is covered in training for Mitsubishi equipment. My Mitsubishi Diamond Elite contractors seem not to know about it though. Or at least this didn't seem to stop them from installing this equipment in what appears to me to be out of spec from the manufacturer.

HVAC Journey: Wall Mounted Mitsubishi Compressor

Posted onAt the end of 2024 my family started a project to remove natural gas / methane service from our house. As part that we began to replace our gas furnace with a heat pump.

The contractor mounted the outdoor unit on the wall of our house in a side alley that kept it out of the way.

This helps save space on the ground and mounting a couple feet above ground gives space for the condensate to drain when in the unit is heating our house. This does not help when the unit is a source of vibration and with the mounting causes structural vibrations in my house.

Mitsubishi has a helpful application note regarding the frequencies of the compressor at various times. During startup of a cycle in the 20-50 Hz range my house would vibrate and could be felt in various rooms through the house.

Pads (the blue/black pieces) were placed in the mounting to help address the issue.

They... might have helped. It's hard to say, I don't really have the tools to measure structural vibration. They did not help enough to avoid driving me crazy every time the compressor started.

What did solve the problem was moving the mounting to the ground.

This addressed the structural vibration issues to the point that I could no longer feel anything in my house.